ANSYS (CAE)

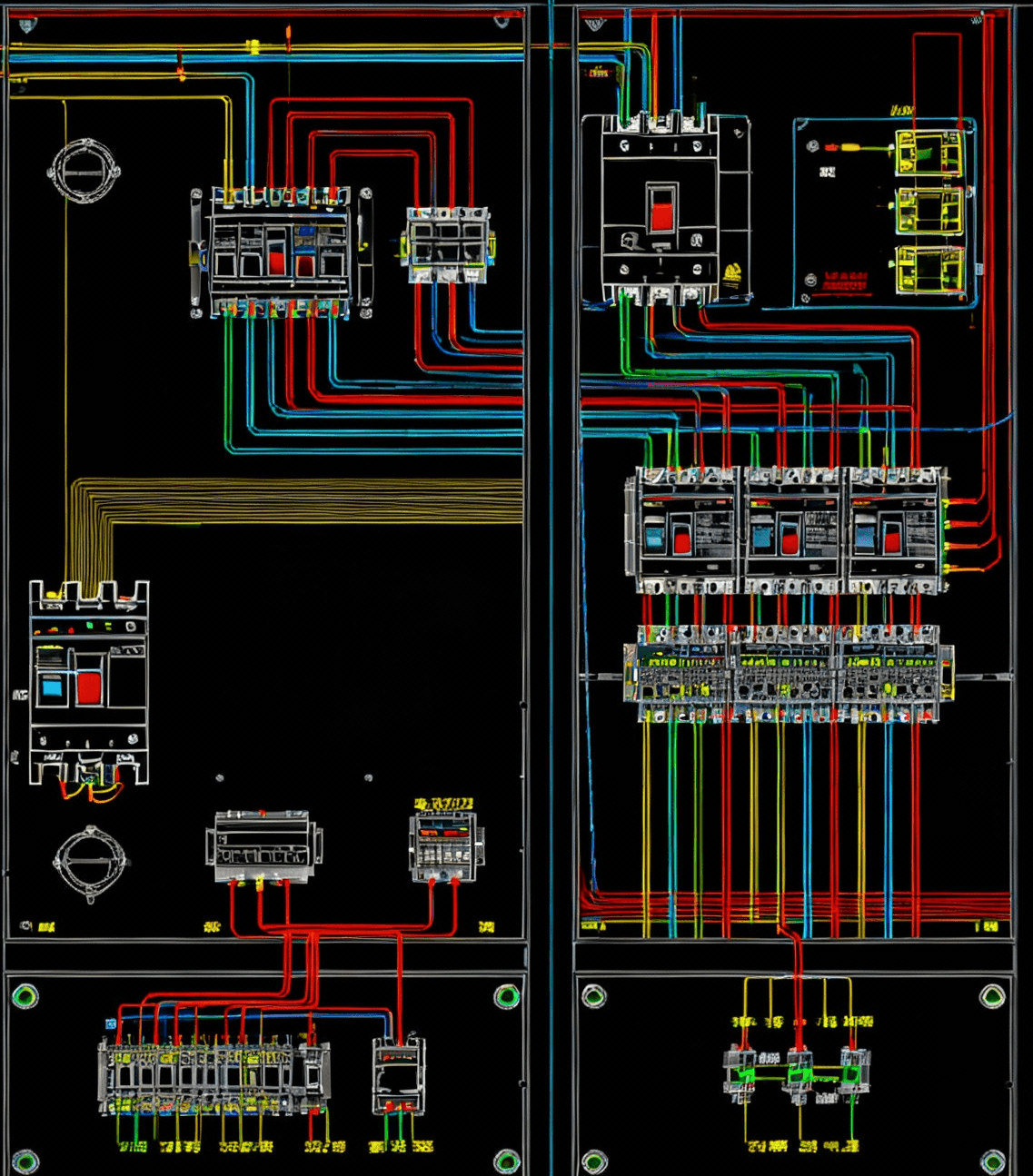

Mechanical, electrical

Min Read

FlexCom is a fast-growing subscription-based SaaS provider that offers cloud communication solutions for businesses of all sizes. Despite their growth, FlexCom struggled to maintain a steady customer retention rate. Their team found it challenging to detect early signs of dissatisfaction among customers, leading to unpredictable churn. Each time a customer canceled their subscription, FlexCom had to spend more on acquiring new customers to maintain their revenue flow, significantly impacting their profitability.

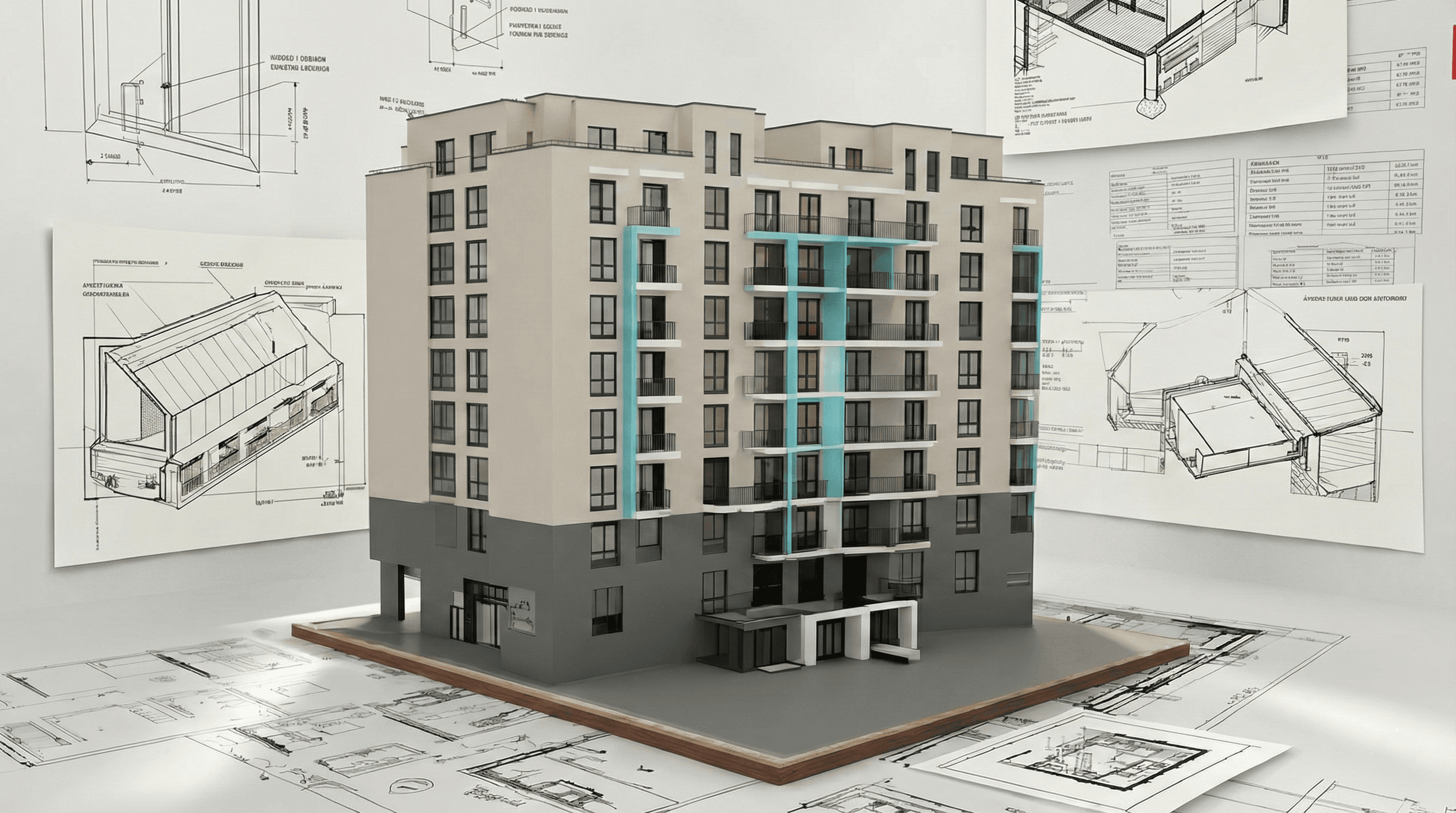

Course Overview

Studio-grade ANSYS training for mechanical, structural, and thermal engineers. Project-based workflows, simulation setup, meshing strategies, multiphysics coupling, and one-on-one mentorship to produce validated, manufacturing-ready simulation reports and design insights.

Why This Course

Turn simulation from a black box into a reliable design tool. This course teaches reproducible ANSYS workflows used in engineering teams: correct physics selection, mesh control, boundary condition setup, result interpretation, and validation. Emphasis is on practical model setup, convergence discipline, and producing actionable reports that inform design and manufacturing decisions. You'll graduate able to run credible studies, avoid common pitfalls, and communicate simulation results to stakeholders.

Who This Course Is For

· Mechanical, structural, and thermal engineers applying simulation to product design

· Design engineers who want to validate concepts before prototyping

· FEM analysts and CAD engineers seeking studio-grade ANSYS workflows

· Graduate students and researchers who need reproducible simulation methods

· Small engineering teams standardizing simulation templates and verification practices

What You Will Build

Module 1—Fundamentals and Model Setup

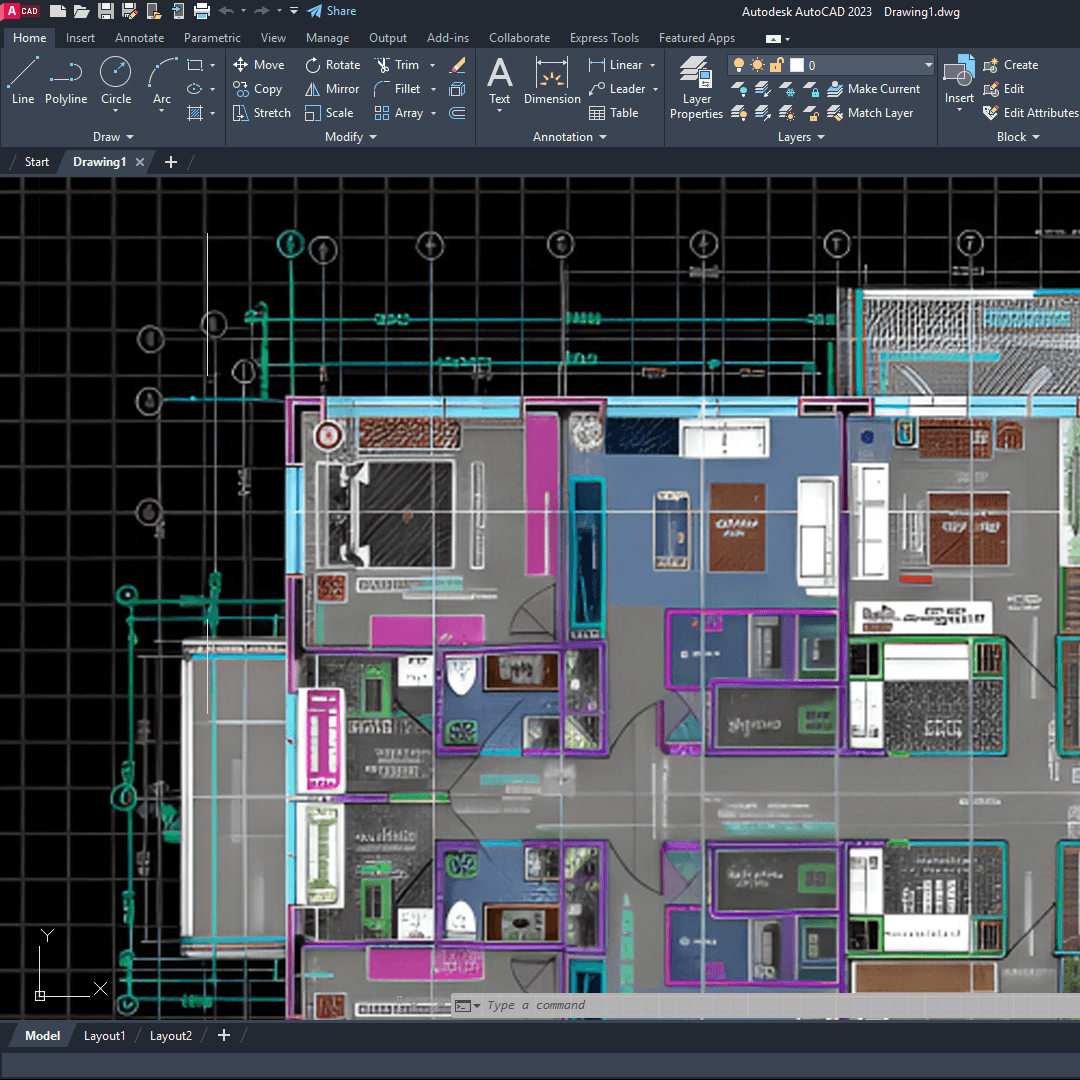

· Geometry import and cleanup workflows from CAD (SolidWorks, Solid Edge, Creo); unit and scale checks

· Physics selection: static structural, thermal, modal, and basic fluid setups; material assignment and boundary condition planning

Module 2—Meshing, Convergence and Solver Control

· Mesh strategies: tetrahedral vs hexa/hex dominant, inflation layers, contact, and mesh refinement for stress concentrations

· Solver settings, convergence checks, and common numerical stability techniques for robust results

Module 3—Multiphysics and Advanced Studies

· Coupled thermal-structural analysis, modal-to-harmonic workflows, basic CFD coupling concepts, and transient study setup

· Contact modelling, nonlinear materials, large deformation, and appropriate solver selection

Module 4—Post-Processing, Validation and Reporting

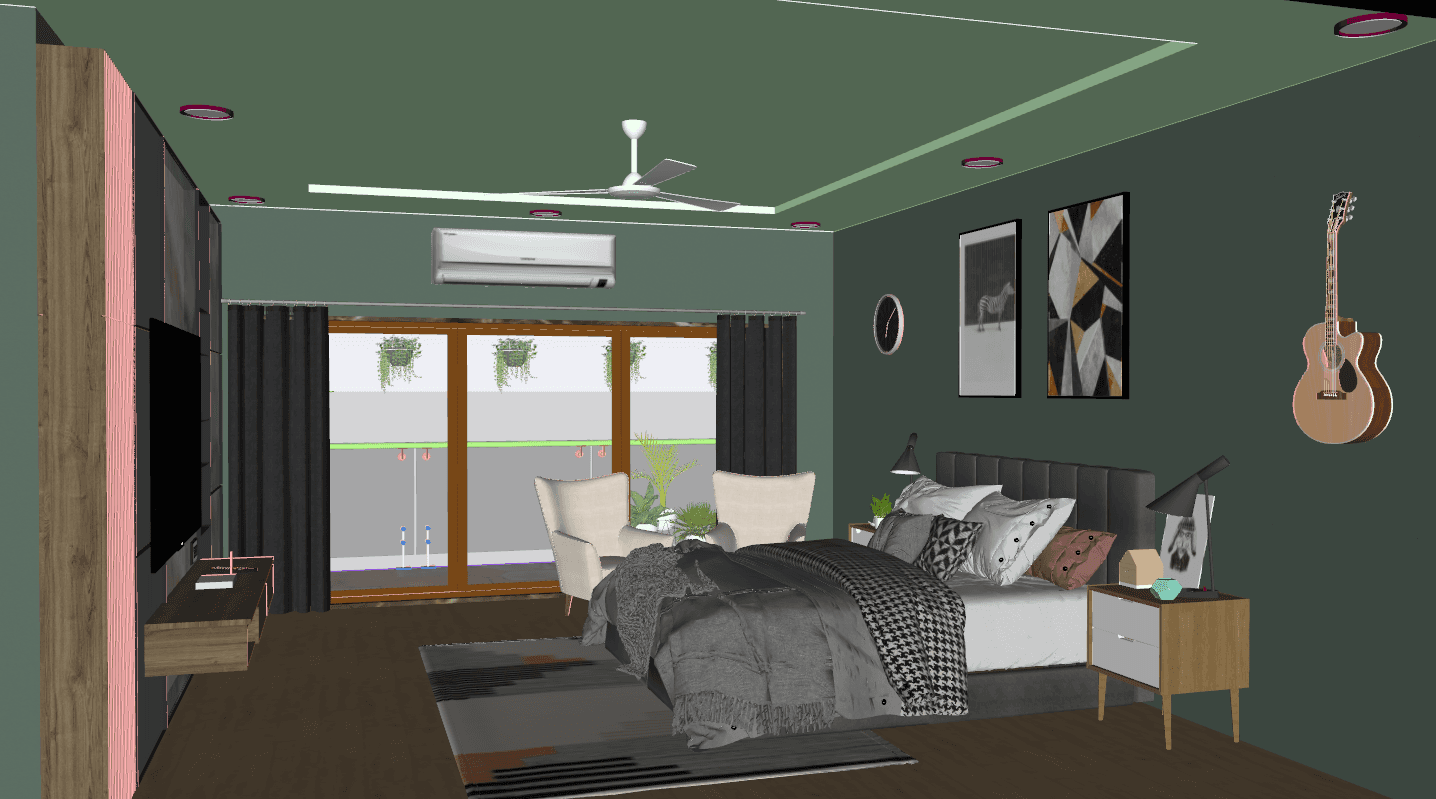

· Extracting meaningful results: stress, deformation, factor of safety, thermal gradients, flow fields, and critical AOVs

· Validation best practices, sensitivity studies, mesh convergence reporting, and preparing client-ready simulation reports with recommended design actions

Capstone Project

· Deliver a complete simulation study: CAD import, model setup, meshing, solver runs, sensitivity checks, validation notes, and a polished report with design recommendations. Each capstone receives a live mentor review and actionable feedback.

Key Features

· Project-Based Curriculum covering structural, thermal, and basic CFD workflows

· CAD Import and Model Simplification best practices for reliable simulation

· Practical Meshing Strategies and convergence discipline to reduce reruns

· Multiphysics Coupling examples and nonlinear/large deformation workflows

· Result Validation, Sensitivity Studies, and automated report templates

· Weekly Live Simulation Reviews and optional one-on-one mentorship for project troubleshooting

· Deliverables Focus: Simulation reports, plots, animations, and exportable result files

· Lifetime Access: Recorded lessons, example projects, and reusable ANSYS templates

Learning Outcomes

· Set up and run production-grade static, thermal, and basic CFD/weakly coupled simulations in ANSYS

· Apply correct meshing strategies and convergence checks to produce trustworthy results

· Model contact, nonlinear materials, and large deformation scenarios with appropriate solver choices

· Perform sensitivity and validation studies and document convergence to support design decisions

· Extract actionable metrics and prepare concise, client-ready simulation reports with visualisations and recommendations

· Integrate simulation into design workflows to reduce prototyping time and lower development risk

Format & Schedule

· Delivery: 100% live online with real-time screen sharing, step-by-step demos, and Q&A

· Options: Small Group Cohort OR 1-on-1 Private Training

· 1-on-1: Flexible scheduling tailored to your project deadlines and model complexity