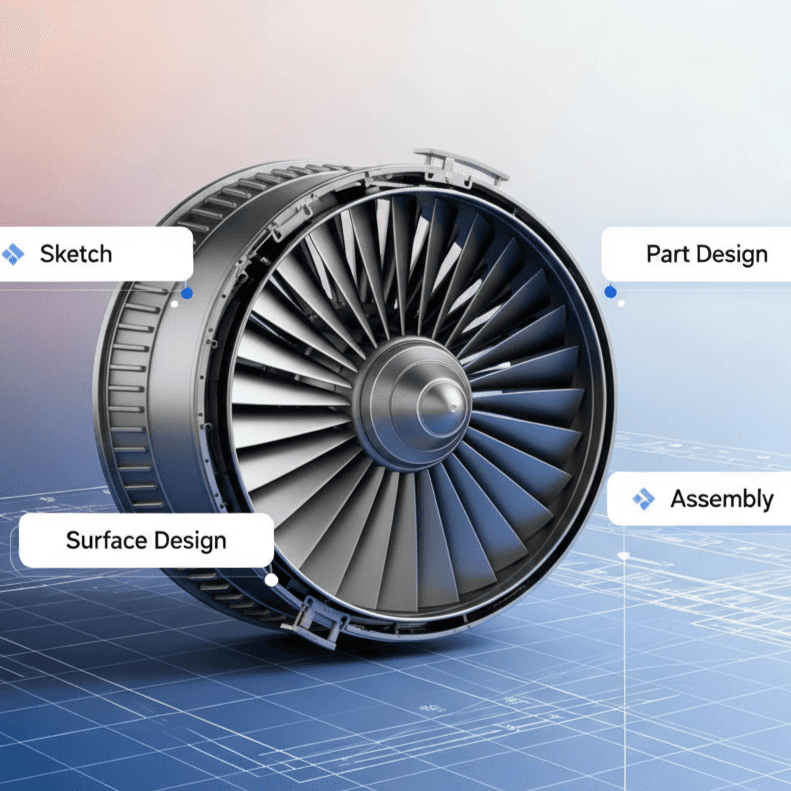

CATIA

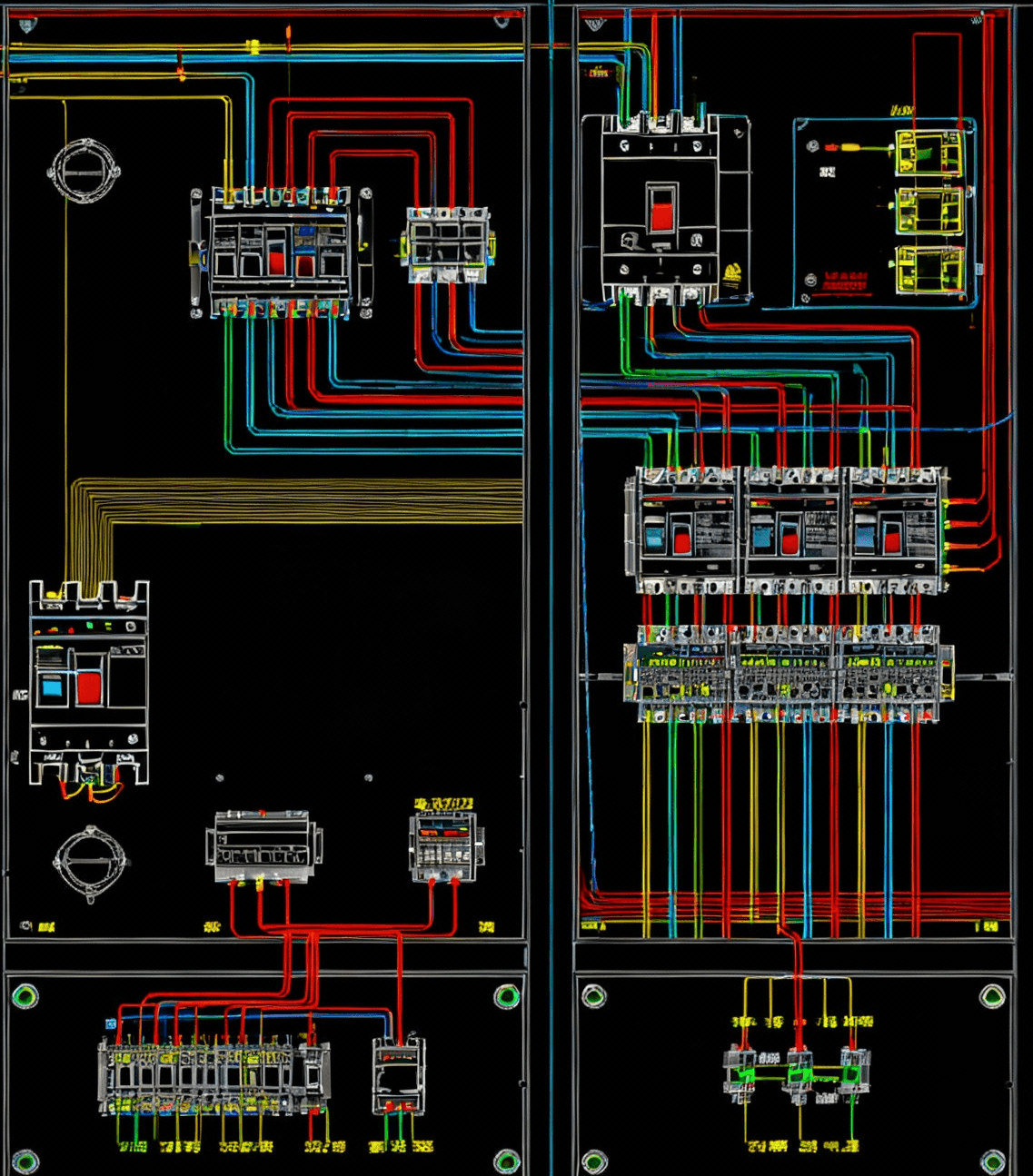

Mechanical, electrical

Min Read

SaaSleek is an AI-powered platform designed to help businesses automate processes, manage customer relationships, and make data-driven decisions with ease. In this tutorial, we’ll walk you through the key features of SaaSleek, showing you how to get the most out of the platform to optimize your operations.

Course Overview

This course teaches industrial CATIA workflows used in product development, tooling, and complex mechanical assemblies. You'll learn when to apply Part Design, Generative Shape Design, DMU (digital mock-up), and Drafting modules to produce manufacturable parts, high-quality surfaces, and fully constrained assemblies. Emphasis is on design intent, model robustness, downstream manufacturability, and repeatable templates so deliverables integrate cleanly with CAM, PLM, and supplier workflows.

Why This Course

CATIA is a premium CAD platform used for high-end product development, aerospace, and automotive tooling. This course teaches industrial workflows so your models are production-ready, collaborate smoothly with large teams, and integrate with PLM and CAM systems.

Who This Course Is For

· Mechanical and product engineers building parts and assemblies for manufacture

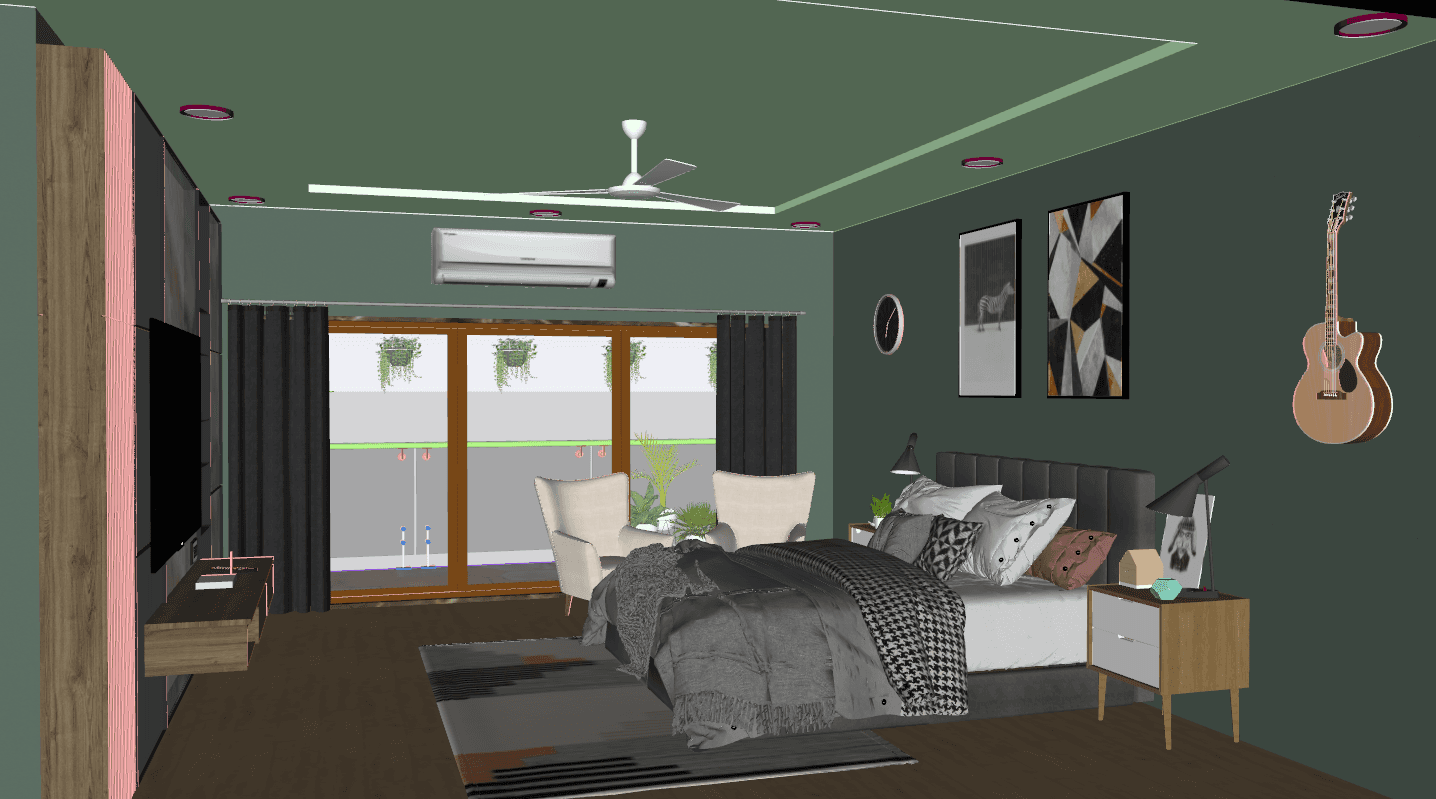

· Industrial designers needing advanced surfacing and Class-A finish techniques

· CAD technicians and detailers responsible for drawings and BOM exports

· Tooling, mould, and fixture engineers preparing manufacturing geometry

· Small teams adopting CATIA for robust CAD standards and collaboration

What You Will Build (Curriculum)

Module 1—Part Modelling and Design Intent

· Parametric sketching discipline, feature planning, best practices for robust part topology, and associative design tables

Module 2—Advanced Surfacing (Generative Shape Design)

· Curve networks, lofting, sweeping, boundary surfaces, fillet strategies, and Class-A surfacing techniques for aesthetic and functional geometry

Module 3—Sheet Metal and Hybrid Parts

· Sheet metal bend/unbend workflows, forming allowances, flange sequences, and integrating sheet metal with solid and surface features

Module 4—Assemblies, Kinematics and DMU

· Large assembly management, constraints and mate strategies, lightweight representations, kinematic simulations, and interference analysis with DMU tools

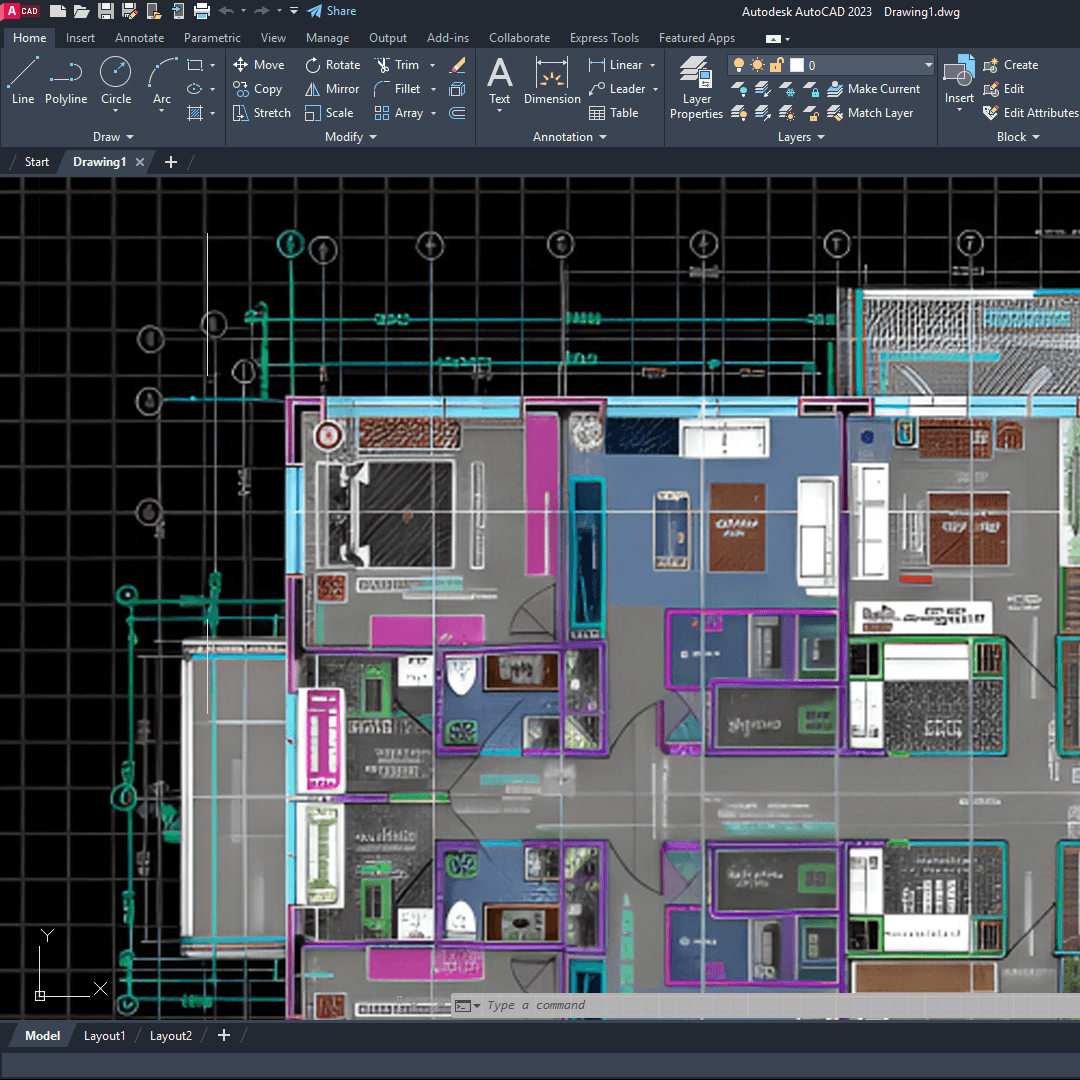

Module 5—Drafting, Tolerancing and BOMs

· Automated drawing generation, views, sections, GD&T basics, custom titleblocks, and BOM extraction compatible with PLM workflows

Module 6—Manufacturing Exports and Downstream Prep

· Preparing models for CAM, NC programming, mould tooling, STL prep for additive manufacturing, and neutral format exports (STEP/IGES) with PMI and metadata

Capstone Project

· Deliver a production package: parametric part(s) or surface-intensive product, assembled model with kinematic check, full drawing set, and manufacturing export bundle ready for supplier handoff

Key Features

· Dual Focus on solid modeling and Class-A surfacing

· Practical Templates for parts, assemblies, and drawing standards

· DMU and Kinematic Checks to validate assembly behavior before prototyping

· Sheet Metal and Tooling Prep workflows for fabrication and moulds

· PMI, Metadata, and PLM-friendly BOM exports for enterprise workflows

· Weekly Live Model Reviews plus optional one-on-one mentorship sessions

· Downloadable Example Parts, Surface Guides, Templates, and export checklists

· Lifetime Access to recordings and course resources

Learning Outcomes

· Produce robust, parametric CATIA parts using Part Design best practices

· Create and control advanced surfaces suitable for high-quality product exteriors and tooling interfaces

· Assemble complex products with efficient constraint systems and perform kinematic/DMU checks

· Generate production drawings with correct GD&T, titleblocks, and automated BOMs

· Prepare CAD data for CAM, mould tooling, and additive workflows using correct export and metadata practices

· Implement CAD standards and templates that reduce rework and improve supplier handoffs

Format & Schedule

· Delivery: 100% live online with real-time screen sharing, demos, and Q&A

· Options: Small Group Cohort OR 1-on-1 Private Training

1-on-1: Flexible scheduling tailored to project timelines and learning goals