Creo (Pro/ENGINEER)

Mechanical, electrical

Min Read

We're excited to announce a major update to our platform that will revolutionize the way you manage your business! At [SaaSleek], we are committed to constantly improving our service to help you stay ahead of the competition. In this release, we’ve introduced several AI-powered features designed to make your work smarter, faster, and more efficient.

Course Overview

This course teaches practical CREO workflows used in product development and manufacturing. You'll learn how to translate design intent into robust parametric parts, manage complex assemblies, create high-quality surfaces, prepare sheet metal, automate drawings, and export for CAM and simulation. Emphasis is on repeatable templates, model resilience, and downstream readiness so your CAD moves smoothly from concept to toolpath and production.

Why This Course

CREO is a professional-grade CAD system that emphasizes parametric design, top-down assembly, and manufacturing integration. This course teaches practical workflows that produce repeatable, manufacturable geometry.

Who This Course Is For

· Mechanical and product engineers building manufacturable parts

· Industrial designers working with Class-A surfacing and aesthetics

· CAD technicians and detailers preparing drawings, BOMs, and CAM exports

· Tooling, mould, and fixture engineers requiring precise geometry and flat patterns

· Freelancers and small teams standardizing CREO practices for faster delivery

Curriculum

Module 1—Foundations and Project Setup

· CREO interface, units, and file management; project templates, naming conventions, and a master modelling checklist

Module 2—Parametric Part Modelling

· Sketch discipline, feature planning, intent capture, patterns, family tables, and robustness strategies for change

Module 3—Assemblies and Top Down Design

· Assembly constraints, top-down/bottom-up methods, large assembly performance, interference checks, and exploded views

Module 4—Surfacing and Complex Geometry

· Curve networks, sweeps, boundary surfaces, freeform editing, surface repair, and transitions from surface to solid

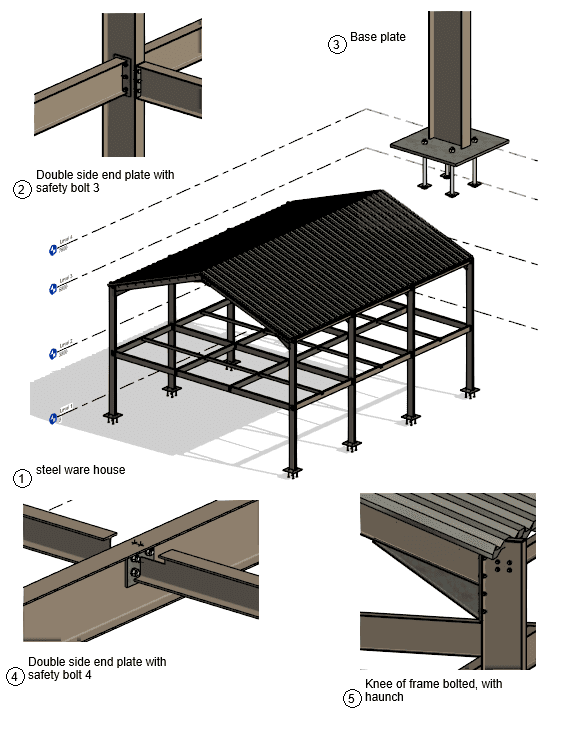

Module 5—Sheet Metal and Fabrication Prep

· Bend/unbend workflows, flat pattern validation, corner treatments, and export prep for laser/press workflows

Module 6—Drawings, BOMs and Automation

· Automated drawing generation, detailed views, GD&T basics, custom titleblocks, annotation automation, and BOM extraction

Module 7—Simulation Prep and CAM Exports

· Simplification and healing for FEA/CFD, export best practices for NC/CAM, STEP/STL/neutral formats, and PMI basics

Module 8—Capstone Project

· Deliver a production package: parametric parts or surfaced product, assembled model with interference checks, full drawing set, BOM, and CAM/FEA export bundle. Includes mentor critique and final checklist.

Key Features

· Project-Based Lessons aligned with industry handoffs

· CREO Templates, Family Table Examples, and reusable feature recipes

· Dual Focus on parametric robustness and flexible surfacing

· Sheet Metal Toolkit and flat pattern validation checks

· Assembly Performance Strategies for large models and exploded/presentation outputs

· CAM and Simulation Prep workflows with export checklists

· Weekly Live Reviews plus optional one-on-one mentorship sessions

· Lifetime Access to recordings, CREO files, and template packs

Learning Outcomes

· Build robust, intent-driven CREO parts that survive design changes

· Implement top-down and bottom-up assembly strategies and manage large assemblies effectively

· Create and refine high-quality surfaces and transition them to solids for manufacture

· Produce validated sheet metal flat patterns and prepare parts for fabrication

· Automate drawings, generate BOMs, and apply basic GD&T for manufacturing clarity

· Prepare CAD data for simulation and CAM with correct simplification, healing, and export formats

Format & Schedule

· Delivery: 100% live online with real-time demos, hands-on exercises, and Q&A

· Suggested Cohort: 6–8 weeks, two 1.5–2 hour sessions per week; weekend intensives available

· 1-on-1: Flexible scheduling tailored to your project timeline